HAIMER - TOOLBASE : DISPENSING SYSTEM | JSR GROUP

HAIMER: WORLDWIDE DISTRIBUTION PARTNER

The Haimer Group is now a global competence partner and offers its worldwide customers WinTool and Toolbase products as a full-service provider.

|

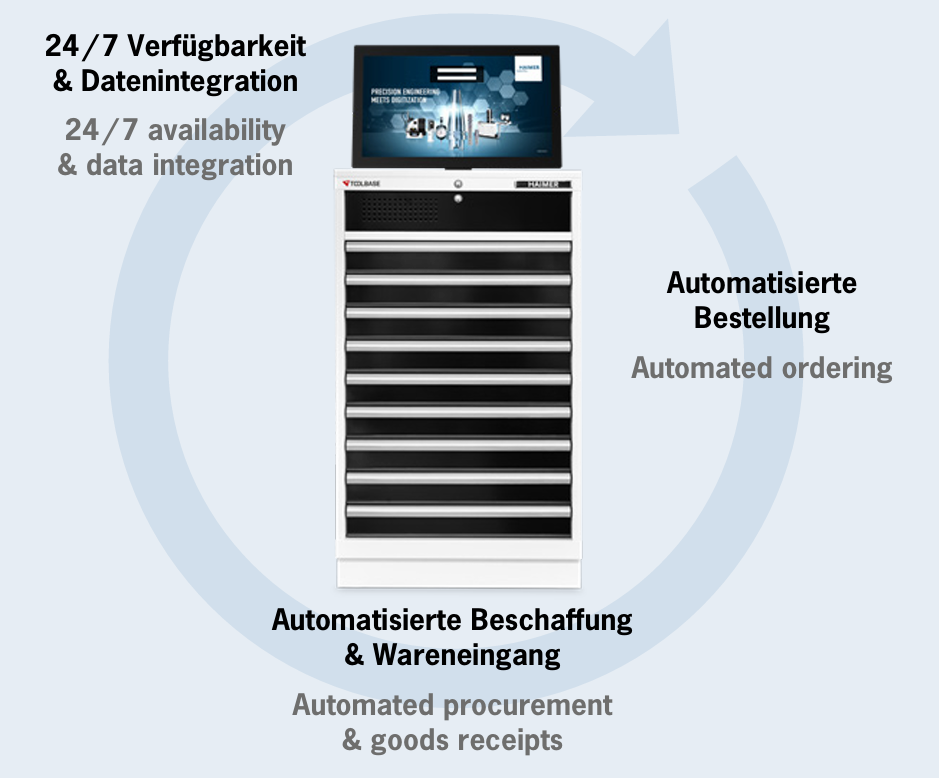

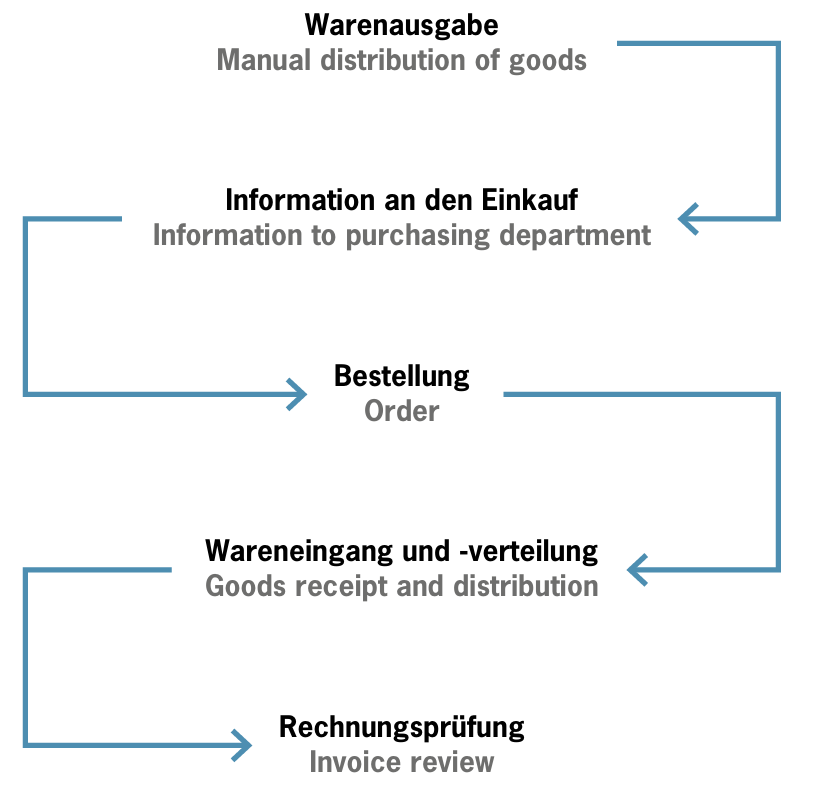

SIMPLE PROCUREMENT With the Toolbase dispensing system customi zed to your needs, cost-intensive processes such as ongoing inventory control, demand determination and ordering via purchasing are a thing of the past.

|

EFFICIENT PROCESSES An automated system reduces your process costs in procurement, while the reliability of the supply for your tools and other consumables increases.

|

SYSTEM SUPPLY Now, everything is automated, with complete transparency at the same time. Current inven tory and consumption data are also available in the shop-floor systems. Process designs, simulations: Everything is simple. At the same time, cost control increases while process costs decrease. |

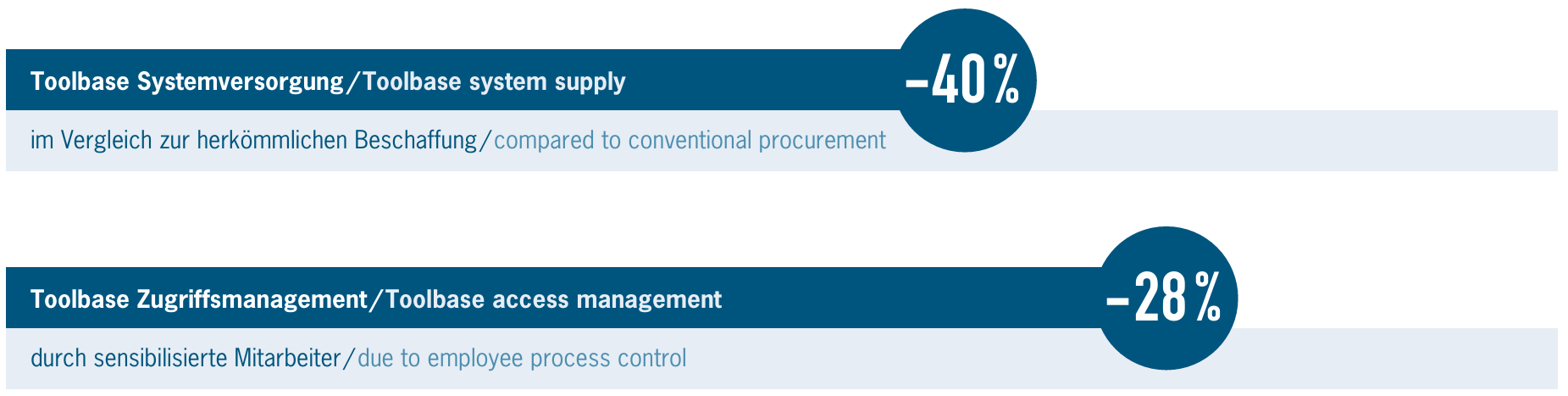

SAVE COSTS WITH TOOLBASE

|

AMORTISATION / AMORTIZATION: 6 - 18 MONATE / MONTHS |

Toolbase systems pay off very quickly. Efficiency potentials for tools and consumables become effective from day one thanks to efficient access management and therefore pinpoint withdrawals as well as an immediate reduction in procurement costs. Accurate consumption data creates transparency and is thus the key to more efficient warehouse management and a reduction in storage costs. |

|

TOOLBASE SYSTEM SUPPLY

|

CONVENTIONAL SUPPLY

|

YOUR BENEFITS

| 1 | INTUITIVE SOFTWARE A powerful system does not have to be complicated! With every further development of our software, we take great care to ensure that the users only see the data on the screen that they currently needs for their current task. Everything else is consistently hidden. This ensures quick integration and minimal training efforts. |

| 2 | SERVER & CLOUD INFRASTRUCTURE Server and cloud solutions instead of individual stand-alone solutions. The ATMS CORE software consistently focuses on networking the systems. This is accompanied by numerous additional functional enhancements that increase the benefits of Toolbase output systems for all users |

| 3 | INTEGRATED TOOL MANAGEMENT Today, the pure storage, output and retrieval of tools no longer meets the high demands placed on an output system as a building block in networked production processes. As a modern tool management system, Toolbase is permanently in exchange with upstream and downstream systems for tool master data acquisition (TOOLTRACER) as well as tool and data management systems (WinTool). |

| 4 | INSTRUCTION & DOCUMENTATION Work equipment such as the tools and articles for personal protective equipment (PPE) handled by people must be holistically recorded in a modern dispensing system, precisely controlled and used in a way that increases productivity. This also includes the possibility of storing training documents and videos and instructing employees accordingly directly at the equipment - including corresponding documentation of the process. |

| 5 | SHARED TOOLS & MEASURING EQUIPMENT MANAGEMENT Not only consumables are in good hands in a Toolbase dispensing system. Many system benefits such as access management, complete traceability and transparency of stocks are also useful for shared tools – e.g. measuring equipment. Toolbase thus ensures that you know the whereabouts of your measuring equipment at all times and that expired test equipment does not even enter production. |

| 6 | VISUALIZATION User experience is becoming increasingly important. With the ATMS CORE visualization engine, not only is the operation of the touchscreen monitor appealing and simple, but you also benefit from the visual representation of the tools and other materials, graphical evaluations (reports) and important information such as cutting values for tools or instructions for the use of personal protective equipment. |